Exclusive IPB manufacturing process!

Exclusive IPB manufacturing process!

Exclusive technology with the whole body only vulcanized at once!

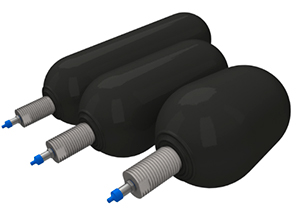

We understand that Bladders with seams are one of these problems. Therefore our bladders are manufactured with the whole body vulcanized at once. The result is a highly reliable part that supports an expansion of up to 20 times the nominal volume.

Grupo IPB Bladders manufacturing process is unique. Developing bladders with suitable materials for each application. The IPB rubber bladder compounds are engineered to be suitable for use under various fluids and severe working conditions, with high elastic capacity.

Grupo IPB manufactures models with a capacity from 100 milliliters up to 820 liters.

* Custom designs – Do not forget to consult our specialists to develop a project in compliance with correct specifications for the work conditions.

Common applications:

- Leak Compensators

- Hydraulic accumulators

- Pulsation dampeners

- Booster

- Volume and pressure compensator

- Fluid Reservoir

TECHNICAL INFORMATION

Standard Nitrile rubber body(NBR) or special compounds, such as Butyl, Neoprene ™, Ethylene-propylene and Viton ™, and others compounds by consulting;

Maximum working temperature according to the compound;

Valves and inserts are supplied in stainless steel by standard, other materials by consulting;

BLADDER MODELS:

WITH GAS VALVE

WITH GAS VALVE

The valves are vulcanized with the bladder body, avoiding breakage and leakage points. Charge valves can be supplied with metal – metal sealing system between the core and valve body, or threaded connection to use external control valves.

With the Open End – NIPPON MODEL

With the Open End – NIPPON MODEL

They do not have a vulcanized gas valve on the rubber body, instead have a open nozzle where the gas feeding is controlled.

* Consult available dimensions.

Accessory feature: anti – extrusion button

Auxiliary device applied to bladders where the accumulator or compensator does not have a anti-extrusion system (anti-extrusion valve). This device is standard for IPB Bladders up to 4 liters.*

*Bladders of any Model or volume can also be manufactured with this device.

Diaphragms for shock absorbers or pulsation dampeners

Diaphragms for shock absorbers or pulsation dampeners

Models K10, K20, K80 – Hydrill, UPETRON, EMSCO e Wirth.

* Also available in our product line: stabilizer and spares parts for the correct functioning of the pulsation damper.

HIGHLIGHTS

Special bladder for Brazilian aerospace research center(DCTA).

Fully customized special bladder for use in rocket motor casing tests.

- Customer: DCTA

- Model: VLS Rocket

- Approximate dimensions: Ø 450 mm x 6000 m

- Approximate weight: 60 kgf

- Useful volume: 820 litros

Besides just manufacturing Bladders, Grupo IPB also has a history of coming up with new innovative ways to use then, check one great example of that on our Solutions Porfolio.