IPB supplies Oil and Gas seals since 1977.

Grupo IPB has always been concerned about providing technology and equipment to execute and manufacture all process of our parts, such as tools, molds and matrices, as well as developing, qualifying and testing our compounds and products

Grupo IPB is not just a seal supplier. We have know-how to assist our customers in developing a custom sealing system including the seal grooves, testing compliance to API and other standards, especially when standard seals are not capable or suitable.

Seal Development

Most important steps for a sealing development process:

- Working conditions identification;

- Performance test and acceptance criteria definition;

- Design seal and groove using AUTOCAD system;

- Developing a suitable a elastomeric compounds in own IPB Laboratories;

- Design and manufacture the appropriate mold;

- Molding of parts;

- Design and manufacture the test performance devices;

- Perform the tests;

- Approve the sealing system with customer and / or third party certifier;

- Provide training for our Clients. Training can be performed at our units, at the customer base or in the field.

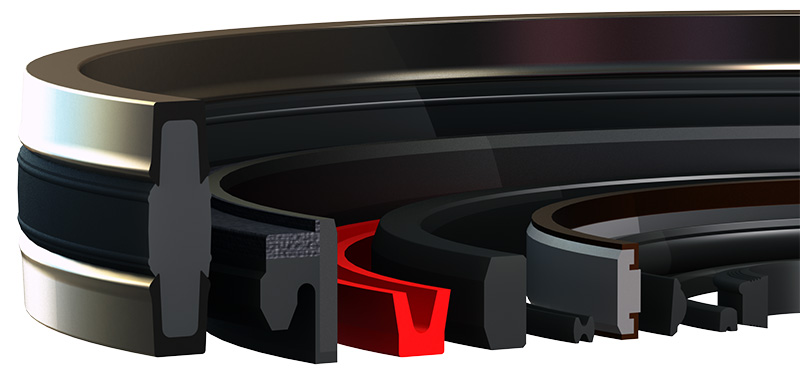

SPECIAL SEALS

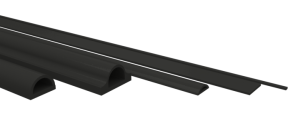

Extruded Profiles

A wide variety of static seal or protection drawn profiles for multiple uses.

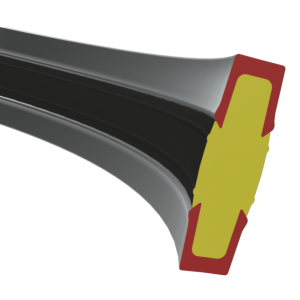

Combined sealing seals

Developed especially for metal X metal seal and high pressure application.

Consisting of metal rings and an elastomeric seal, that performs a secondary seal and spring effect.

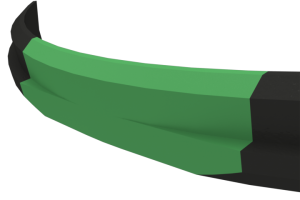

Shear gaskets

Developed to certify a perfect lock of wear bushing in subsea equipment up to a limit of a specific load.

When the specific load or pressure is applied the gasket shears and release the installation tool.